Starting work on the conrod. Mounted up via the chucking piece in the lathe, and then I’ve set the topslide over at an angle to match the taper. Gentle cuts to remove the casting marks and generally tidy the part up:

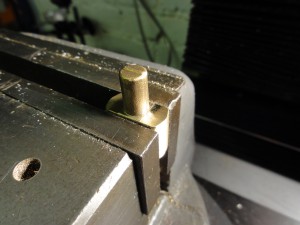

Once thats done, the conrod is mounted in the milling vice to drill the through holes. Doing this before splitting the part should hopefully help alignment. Here I’ve used a milling cutter just to flatten of the surface to allow for more accurate drilling. I’ve also used the edge finder to align the part accurately on the X axis under the spindle.

Moving to the lathe, I’m using a wiggler to get the part centred in the 4-Jaw for the drilling and facing operation.