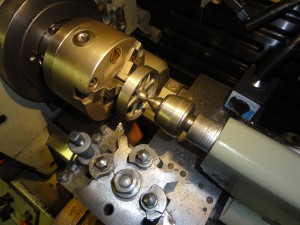

Once cleaned up by filing, the flywheel can usefully be mounted using the outside of the jaws in the three jaw chuck, and was fairly centrally aligned. This allows for gently tidying up all the accessible edges of the casting and sizing the hole for the crank shaft.

With that done, I mounted the flywheel on a scrap piece of 9/32 stock to perform the rest of the turning – hopefully that will ensure it’s nicely concentric when mounted on the engine. With only the setscrew holding it in place gentle cuts are the order of the day, and I’m using my new (to me, anyway) live centre to add support and prevent chatter.

Flywheel in position – starting to look like something now !