After a poor silver soldering attempt some more 9/32 stock has been ordered for a second try. I’ve bonded the web blanks together with some cyanoacrylate to try and ensure concentricity. I’m also using a tip picked up from Markus Neeser (his website is here – lots of useful stuff). He suggests making a a small area of the crank pin a press fit into the web – hopefully preventing the solder escaping onto the pin.

Here are the webs again, being formed into shape by filing. I’ve lightly countersunk the holes where the pin will fit to ensure a tight seat on the shoulder. Careful not to go too far and undo the good work with the press fitting diameter of the pin !

And the assembly pre-soldering – the pin was a lovely press fit into the webs.

Post soldering – and then pickled in citric acid (in the form of cheap descaler tablets)

Cut the waste section from the middle of the webs with a hacksaw, and then clean up with a slot drill

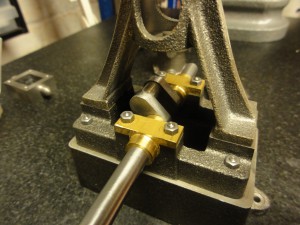

And installed into the bearings: